Projects

Bayswater Bridge - Bayswater

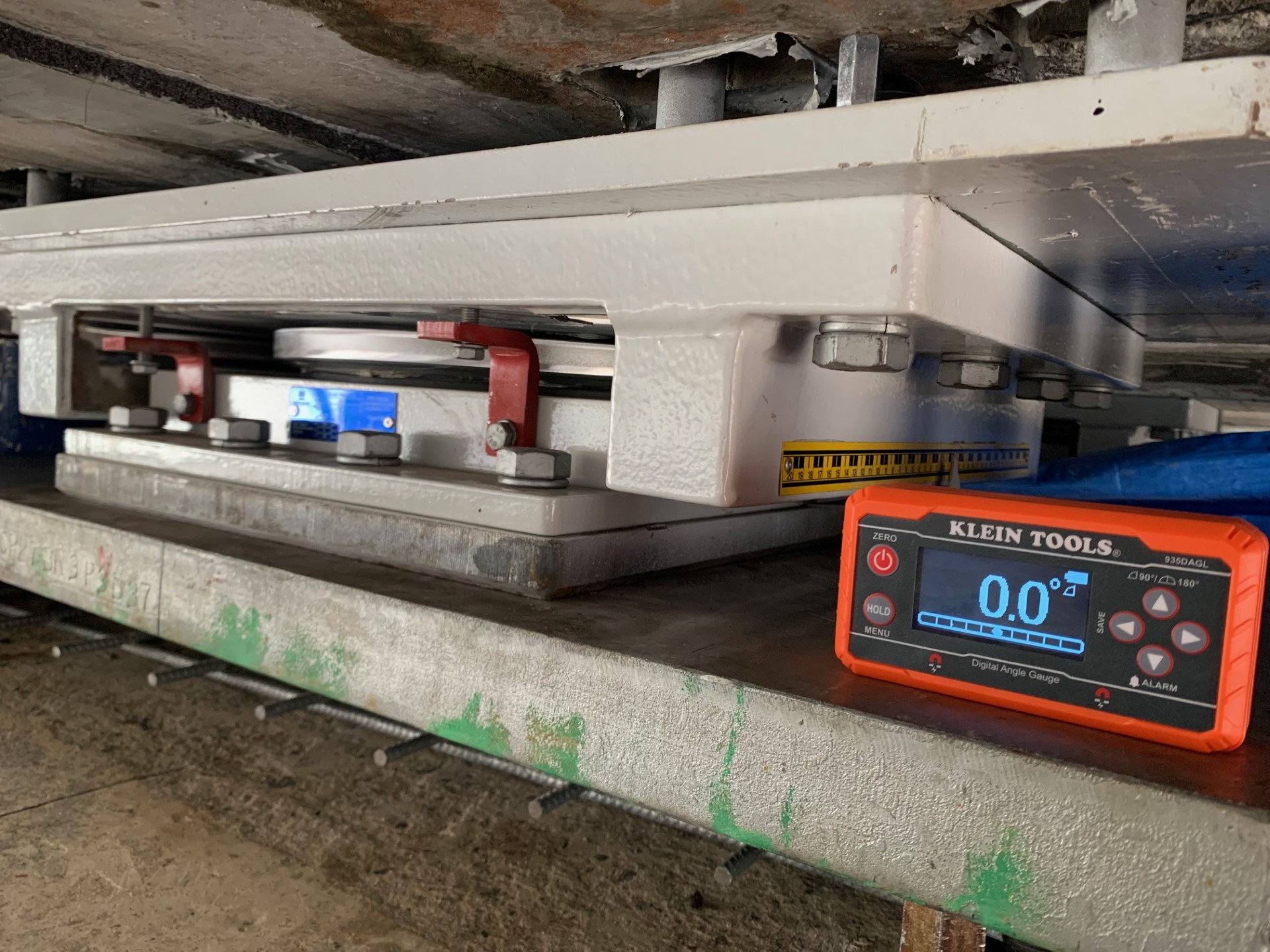

Using a synchronized hydraulic pump, we facilitated precise and controlled lifting and lowering. Throughout this process, we utilized various lockring jacks, including 60-ton, 100-ton, and 200-ton hydraulic jacks. The scope of work also included: • Bearing installation and levelling: We assisted with the installation and leveling of the top and bottom plates of the spherical bearings. • Epoxy grouting: We also assisted with grouting the bearings, ensuring long-lasting durability. Although formwork was not included in our scope for this project, we have the capability to perform it when needed. • Duct repair: We repaired damaged ducts within the bridge beams using an innovative solution that involved an inflatable bladder and a specialized grouting method.